Electrical Appliances Test and Tag Brisbane

Our licensed electrician provides Test and Tag of electrical appliances throughout Brisbane. Testing and Tagging of electrical equipment, electrical distribution system is carried out in compliance with the Australian regulations such as AZ/NZS 3760, Electrical Safety Regulations 2013 and AS/NZS 3012 . We provide same day, on-site inspection ensuring the safety of your home and workplace.

Get The Best Quote on Test & Tag by Filling Up This Form

What Kind of Electrical Appliances Should be Tested & Tagged?

The aim of testing and tagging is to check if the electrical and electronic appliances are functioning correctly. Test and tagging is a preventative maintenance procedure.

Any electrical and electronic devices that has a voltage of less than 50V and has a detachable plug (portable) is to be tested and tagged by a licensed electrician. In addition, plug-in appliances are subjected to the inspection, test and tag requirements. Any extension cable or harness used in a workplace or industry is acceptable as long as it is up to 2.5 m in height.

Kettles, Washing Machines and Toasters. Two levels of protection: earth wire & basic insulation

Appliances with dual or two insulation layers. Also, referred as double insulated appliances. Examples are, dryers, lawnmowers, and drills.

Who Should Do Testing and Tagging?

The need for Test and Tag is to ensure a safer workplace and to avoid any electrical hazards caused by electronic appliances and devices.

Testing and Tagging should be carried out by a licensed electrician with a substantial experience and has a sound knowledge and understanding on safety regulations and standards such as AZ/NZS 3760, Electrical Safety Regulations 2013 and AS/NZS 3012 standards.

Wayne Heydon, a licensed Master Electrician at ENC Solutions Today has over 30 years of experience and has carried out hundreds of Testing and Tagging of electrician appliances throughout Brisbane region. You can call him at 0432 685 965 or click the link below to get a cost-effective quote.

FAQs on Testing and Tagging of Elecrical Equipments

Wayne Heydon, our licensed Master Electrician is here to answer your queries on Testing and Tagging

The cost of testing and tagging varies depending upon the number and types of appliances to be tested. The price is estimated at an hourly basis. The quote will depend on how many items require testing and tagging. To get an approximate costing, kindly call our licensed electrician at 0432 685 965 or send us your requiement by clicking the link of the below get quote form,

Get Quote for Test and Tag in Brisbane, Qld for Electrical Appliances (encsolutionstoday.com.au)

The entirety of your work place must be tested and tagged; this includes:

- All office areas

- Factory

- Laboratory

- Workshops / tool rooms

- Kitchens, dining areas and lunch rooms

- Waiting and lounging areas

- Bathrooms and showers

- Spa and pools

- Classrooms / training rooms / meeting rooms

- Construction areas

- Temporary locations

- Car parks

- Manufacturing areas

- Retail sales areas

- Walkways / Hallways if necessary

Upon completion of the job, we will provide you with a comprehensive report within 24 to 48 hours. In case of urgent requirement, please do let us know and we will expedite it.

The legislation requires testing and tagging records to be kept for a minimum of 7 years or for the life duration of the equipment (whichever is greater). If you lose your report, you can re-order from the electrician who completed the test and tag.

Our licensed electrician has over 30 years of experience in providing electrical and testing and tagging services to all the suburbs of Brisbane and SE Qld (Queensland).

How Often Should Electrical Appliances be Tested and Tagged?

Standard rules pertaining to the building and mining industries require them to test and tag their electronic devices every three months. Due to unfavorable conditions from the industries that may result in flaws on the electric equipment, the need for testing and tagging the appliances is necessary. Every three months, the test and tag color are changed. According to the different lengths of time each year, this aids in grouping the tags into the same months that they fall within.

Australian Standards and regulations such as AS 3760 Standard, stipulates the frequency of test and tag as per the workplace and environment.

Get Best Quotes for Testing and Tagging of Electrical Appliances by our Licensed Electrician

Benefits of Test and Tag with ENC Solutions Today

Test & Tag Benefit # 1

Detects the Devices Malfunctions and Abnormalities

Test & Tag Benefit # 2

Prevents Potential Electrical Hazards

Test & Tag Benefit # 3

Brings the company into compliance with the safety regulations

Test & Tag Benefit # 4

Directs employees to the correct usage of electrical equipment

Test & Tag Benefit # 5

Lowers the risk of fines

RCD Testing & Tagging Services

ENC Solutions Today can test both portable and fixed RCDs, which are also known as ELCBs and the Safety Switch, in Gold Coast.

The RCD Trip Time is a measurement of how long it takes the RCD to respond when a dangerous situation occurs. The RCD Test Instrument simulates a fault, and records the operating time of the RCD in milliseconds (ms). This test therefore demonstrates how quickly the RCD will respond to a dangerous situation. RCDs generally respond in under 30ms, however up to 40ms is acceptable under certain circumstances.

During the RCD Ramp Current Measurement, the RCD Test Instrument simulates an earth leakage current (which represents a dangerous fault), however this time, the instrument starts the leakage current gradually, and “ramps” the current up over say 15 seconds. The test instrument then records the earth leakage current in milliamperes (mA) at which the RCD trips. This test demonstrates how sensitive the RCD is in detecting a dangerous situation. Generally, RCDs must respond at 30mA or less, although some special RCDs are set to respond at either 10mA or 100mA

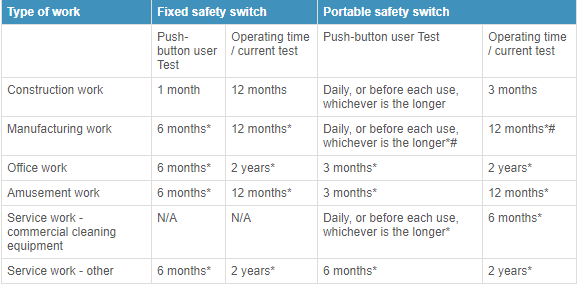

Intervals for testing specified electrical equipment

The type of work being performed determines how often specified electrical equipment is tested. Specified electrical equipment is defined by section 97 of the Electrical Safety Regulation 2013 as electrical equipment with a current rating of not more than 20 amps*. Specified electrical equipment also includes cord extension sets and electrical portable outlet devices (EPODs). *For service or office work, specified equipment is limited to equipment that is moved during its normal use for the purpose of its use.

The table below outlines the maximum interval between tests.

Note: there are specific requirements on a hire company for inspecting, tagging and

testing hire equipment.

Intervals for testing Type 1 and Type 2 safety switches

For construction work, refer to AS/NZS 3012 Electrical installations – Construction and demolition sites

For all other work, refer to the Electrical Safety Regulation 2013 and,

where applicable, AS/NZS 3760 In-service safety inspection and testing of electrical equipment.

Get The Best Quote on Electrical Services Brisbane, Qld

Image Attribution:

- by rawpixel.com on Freepik

- by pvproductions on Freepik