Maintenance, Insurance Repairs and Test and Tag

Test and Tag is the name given to the process of checking the safety of portable electrical appliances.

It involves two parts: first visually inspecting the appliance for any damage, followed by electrically testing it with a Portable Appliance Tester.

Once tested, the item is placed with a tag to confirm that it has in fact been tested, along with showing who tested it, the test date and when the next test is due.

The primary reason behind doing testing and tagging is to ensure the safety of the people in the workplace coming into contact with the appliance, while also minimising the risk of an electrical hazard.

The AS/NZS 3760 is the Australian Standard that provides guidelines and regulations for the test and tag industry with regards to electrical safety of appliances. It sets out recommendations to issues such as test and tag intervals, defines who can test and tag and general guidelines.

Intervals for testing specified electrical equipment

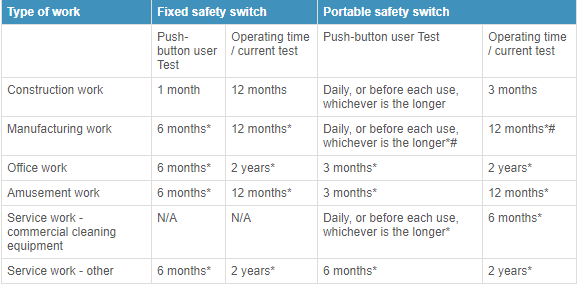

The type of work being performed determines how often specified electrical equipment is tested. Specified electrical equipment is defined by section 97 of the Electrical Safety Regulation 2013 as electrical equipment with a current rating of not more than 20 amps*. Specified electrical equipment also includes cord extension sets and electrical portable outlet devices (EPODs). *For service or office work, specified equipment is limited to equipment that is moved during its normal use for the purpose of its use.

The table below outlines the maximum interval between tests.

Note: there are specific requirements on a hire company for inspecting, tagging and

testing hire equipment.

Intervals for testing Type 1 and Type 2 safety switches

For construction work, refer to AS/NZS 3012 Electrical installations – Construction and demolition sites

For all other work, refer to the Electrical Safety Regulation 2013 and,

where applicable, AS/NZS 3760 In-service safety inspection and testing of electrical equipment.

Electrical Insurance Repairs

EnC Solutions are fully licensed contractors who carry out all type of Electrical Works which are

under insurance. Currently, EnC Solutions are providing insurance related repairs and

maintenance works for Queensland area. The objectives and goals of EnC Solutions is to provide

highest degree of customer satisfaction and ensuring a best possible solutions.

EnC Solutions can assist you with claiming for electrical damage. We can assess the damage,

the cause and extent of the damage and then we can provide a written report stating the cause

of the damage and give a breakdown estimate of materials and work needed to be done as

result of the electrical fault.

The success of electrical insurance claims mainly relies upon the type of insurance cover you

have and the cause of the electrical damage.

Electrical Maintenance Works

With Just In Time approach, EnC Solutions provides rapid deployment of Electrical Maintenance Works in compliance to safety standards. In case of electrical breakdown, we assure the earliest possible service delivery to the concerned location

Routine Electrical Maintenance

As the saying goes, Prevention is better than Cure, EnC Solutions provides Programmed Preventive Measures (PPM) in monthly or in 6 months intervals basis. This ensures your electrical devices and systems are performing as they should. Preventative measures help your business eliminate vulnerability to safety hazards and protect employees from unnecessary harm.